APPAREL PRE PRODUCTION MEETING GUIDANCE

1.1 Overview

The objective of the Pre-Production

Meeting (PPM) is to:

- Review all details and production requirements of production prior to bulk cutting.

- Facilitate early detection of all potential production issues and develop appropriate action plans and solutions prior to bulk production.

- Identify quality process control points

- Avoid last minute quality failures due to lack of or missing style information prior to bulk production.

- Validate factory production capacity and lead time for on time

delivery quality product.

- Address all quality callouts prior to bulk production

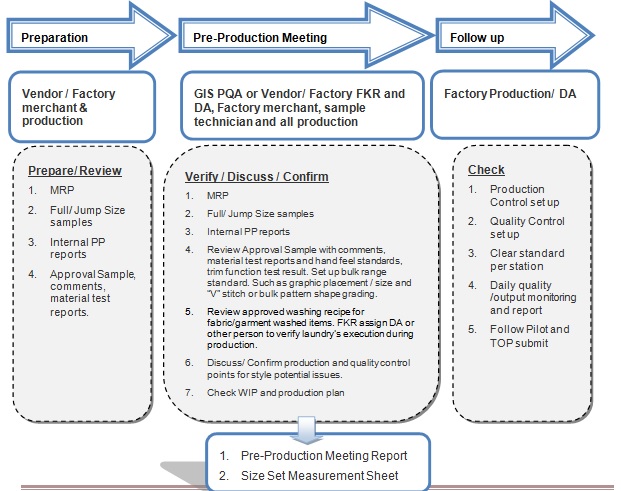

1.2 Pre-Production Meeting Flow Chart

| Section 2: Pre-Production Meeting Preparation | |||||

2.1 Vendor / Factory Preparation

Prior to the Pre-Production Meeting, the

Vendor / Factory merchant and production team is responsible for validation and

preparation of the following:

- A completed Manufacturing Ready Package (MRP).

- Ensure Final Fit approved sample and all factory pattern and

fit issues are reconciled before PP meeting.

- Collect pre-production sample’s measurement and comments on

aesthetic and key QA control points before PP meeting.

- Verify receipt of all bulk fabrics and trims.

- Prepare 3rd Party bulk garment test report and

internal lab test report for fabric or trims

- Prepare full / jump size set sample in bulk fabric from factory

production once a final GSS with size set comments is available.

- For high risk styles, need to contact buyer QA to schedule the PP meeting with at least 5 days advance notice. For denim high risk styles due to washing process, please refer to GAP Source Library/Quality Assurance/ Quality Manuals SOP Guidelines/ Wet Processing PPM SOP for further details

- For repeat styles, needs to ensure all the MRP data with approved samples are correct and workable for coming bulk production. All previous approved standards should be reviewed. If the previous approved standards cannot be achieved in current production, factory should submit updated approval sample. For repeat styles, the approved sample / standards is valid for maximum 2 seasons only.

2.2 Prepare Factory Jump / Full Size Set for Pre-Production Meeting

The Factory Jump / Full Size Set are the

samples reviewed during the PP Meeting.

These samples should be

prepared by production factory. A PP

sample will be made of the following:

1.

Bulk fabric and full color if

possible

2.

Sewing

construction and measurement follow Brand approved sample final comments.

3.

Right

label placement.

4.

Use bulk trims such as zippers,

buttons, interlinings, thread, labels, etc. If bulk trims are not available

then any available trims for placement purpose will be sufficient

5.

Actual bulk washing effect and hand

feel

6. Actual bulk embroidery and print, if needed

2.3 BUYER QA or QA/INHOUSE Preparation

Prior to the Pre-Production Meeting, the QA/INHOUSEor Buyer QA team is responsible for the following:

- Confirm vendor / factory production teams’ readiness and arrange for the PP meeting.

- Study the MRP file and review product specific key construction tips before PP meeting.

- Review kids/baby product safety recommendations from the line review report

- Buyer QA/ QA/ Inhouse and Factory Production teams discuss key quality callouts on aesthetic and construction.

- Review the full / jump size set sample with QA before the PP meeting to identify potential production issues.

- Communicate with buyer office/Head for request / clarification of missing information/ samples.

2.4 Timing

- Before bulk cutting and knitting commences for each style

- Factory receipt of bulk fabric and key trims

- Full jump size set samples are ready

- Final approved fit sample and all fit / pattern issues reconciled

- MRP information for Phase I is complete before PP meeting

5.1 For key critical elements missing, the PP meeting

will be delayed until Vendor/Factory completes the MRP. Critical elements are the following: Brand

Approved Sample with Comments, Final GSS/techpack and Fabric Swatches…..etc.

5.2 In case the MRP information is incomplete; Buyer QA / QA /Inhouse will follow up and ensure all elements are completed prior to bulk

production.

6. Repeat styles have PP meeting once per every 2

seasons prior to bulk production.

2.5 Manufacturing Ready Package (MRP) Information

The MRP file is the master source of record

that contains all of the production requirements for the style. A complete MRP file reduces the likelihood of

future quality issues because all style components are reviewed and discussed

during the PP meeting. When sections are

incomplete, the opportunity for potential quality issues in bulk production

increases.

Factory should have Phase I material

completed for the PP meeting while getting the Phase II material complete

before the corresponding bulk process starts. By the Final inspection, all the

required material in MRP should be complete. The following information must be present in the MRP

file.

|

|

Before …

|

||||

|

|

Phase I

|

Phase II

|

|||

|

MRP Information

Key MRP elements highlighted in yellow

|

PP Meeting

|

Bulk Production

|

Washing

|

Packing

|

Final Inspection

|

|

PO Details = Confirmed

Placement Sheet (CPS)

|

ü

|

|

|

|

ü

|

|

Final GSS & BOM

|

ü

|

|

|

|

ü

|

|

Brand Approved Standard Sample

(green tag sample) with Comments

|

ü

|

|

|

|

ü

|

|

Approved fabric swatch and

hand feel standard ( Print / strike off)

|

ü

|

|

|

|

ü

|

|

Embroidery/printing and

placement

|

√

|

|

|

|

ü

|

|

Approved washing

recipe for fabric/garment washed items (Signed off by FKR).

|

√

|

|

|

|

ü

|

|

Approved trims

card (main label & care labels,

buttons/snap, zipper, thread, lining, interlining, twill tape…)

|

√

|

|

|

|

ü

|

|

Full/Jump Size Set sample with

comments

|

√

|

|

|

|

ü

|

|

Label & marketing trim placement

|

ü

|

|

|

|

ü

|

|

Line review reports (for Kids

& Baby)

|

ü

|

|

|

|

ü

|

|

For all baby’s apparel/ soft accessory having light duty (12-16L) ring snaps: 24-hour Snap

Attachment Strength Test Report

|

ü

|

|

|

|

ü

|

|

Fabric/yarn test reports

|

ü

|

|

|

|

ü

|

|

3rd Party Fabric Inspection

Report, if applicable

|

ü

|

|

|

|

ü

|

|

Pre - Product Meeting Report /

Size Set Measurement Sheet

|

ü

|

|

|

|

ü

|

|

DCPO

|

|

√

|

|

|

ü

|

|

Approved trims card (price

ticket, hangtags, size sticker, polybag, plastic pin, tissue paper, hanger

if applicable…)

|

|

|

|

√

|

ü

|

|

Additional approved shade lots

and hand feel for all color

|

|

ü

|

|

|

ü

|

|

Lab Testing Reports: Mock Up Test,

Pull Test, Garment Test

-

For ALL baby’s apparel/soft

accessory having Japan orders: Additional Formaldehyde Test Report per S2

sampling plan issued by Japan lab.

-

For styles mentioned in full

garment test report as high risk in flammability (wearing apparel/scarves for all genders)

: Additional Flammability Test Report per sampling plan listed in Softline

Manual / Flammability Chapter, Table 1 & 2.

|

|

ü

|

|

|

ü

|

|

Approved wash standards and

shade-bands once approved by SFGP.

|

|

|

ü

|

|

ü

|

|

Folding detail / Packaging details

|

|

|

|

√

|

ü

|

|

Factory Production Plan (WIP)

|

|

√

|

|

|

|

|

Additional correspondence from

VM if applicable

|

As

needed

|

As needed

|

As needed

|

As needed

|

As needed

|

2.6 Roles & Responsibilities

1. Buyer QA

|

Position

|

Responsibility

|

High Risk Style

|

Standard Programs

|

|

Buyer QA Team

|

1.

Facilitate

preproduction meeting

2.

Double

check MRP readiness prior to bulk cutting

3.

Find out all

potential quality issue with recommendation before mass production, special

on construction and functional / small part issues (i.e. pocket opening

construction, small part, etc)

4.

Review

kids/baby product safety callouts

5.

Follow up

on factory’s production and quality control points

|

For fully empowered factories, QA and Inhouse participate; For non-empowered factories, buyer QA participates.

|

.

Buyer QA only participates for non-empowered

factories.

|

|

Vendor Management Team

|

1.

Convey key aesthetic details

2.

Communicate requirement of the product

3.

Review MRP with approval stamp for production and inspection ref.,

4.

Follow-up with Vendor / Factory on fabric, trim, and wash standards

5.

Follow-up with brand to resolve inconsistencies with program standards

|

Optional

|

Optional

|

|

Fitting Technical Team

/ Wet Processing for Denim / Product Safety Team

|

1.

Convey

technical fit history to buyer QA/Factory

2.

Pattern

and sewing technical advice to ensure bulk can achieve as approved sample

3.

Conduct

fitting on form and review GSS/techpack to ensure grading and tolerance is bulk

achievable.

4.

Wet/dry

processing standard/ shade band approval and bulk control points suggested.

Details should refer to GAP Source Library/ Quality Assurance / Quality SOPs/

Wet Processing PPM SOP.

5.

For Baby

& Kids product, please refer to line review report and contact Product

Safety team for questions.

|

By Special

Request

|

Nil.

|

*Via

Conference Call, Video Conference, In Person as needed

2. Vendor / Factory

Factory attendance in the PP meeting is required to

cover the following areas of production responsibility.

|

Factory Representative

|

Responsibility

|

High Risk Style

|

Standard Programs

|

|

Production

|

1.

Production

plan & Delivery Lead time review

2.

Set up of

bulk production control points and ensure actions executed across all

departments.

3. Prepare the Full/Jump size set samples.

|

ü

|

ü

|

|

Factory Key Representative and

DA

|

1.

Review MRP file with complete information

2.

Check PP sample

construction meet Gap testing standard before PP meeting (special

concentration on small part, functional pocket construction, etc)

3.

Check Full / jump size set

4.

Set up Bulk checking on Quality/Visual/Measurement / Product Safety to

ensure it consistently meets GIS requirement.

5.

Review Fabric & Trims testing and inspection reports

6.

Discuss and record key QA product control points and prepare PP report

|

ü

|

ü

|

|

Merchandising

|

1. Prepare all approved sample/ trim card/ MRP and

production Time & Action communication with all parties ready to do the

job right from the beginning

2. Confirm PO details and bulk fabric/trim are ready

in factory

3. Distribute

documents and samples within production teams to ensure all the PP meeting

information and standards were clear and complete

4. Follow

PP report and communicate to GIS VM, PQA, PI, and WP. ….etc for clarification

/ further standards when needed.

|

ü

|

ü

|

|

Patternmaker / Cutting

|

1. Review technical construction details of Full/Jump

size sample to meet GIS Quality / Visual/ Product Safety Requirement.

2. Advise

the Fitting requirement by fitting on dummy.

3. Pattern and sewing technical advice to production

line

4. Prepare bulk patterns after review shrinkage test

5. Confirm cutting direction/ fabric face for cutting

|

ü

|

ü

|

|

Laundry / Finishing

|

1. Washing formula vs. hand feel

2. Shrinkage allowance control by lot

|

ü

|

ü

|

|

Pressing / Packing

|

1. Pressing and folding method

2. Packing method, Carton size, and Shipping marks

|

ü

|

ü

|

Each party is

responsible to have answers ready of pending issues.

3.1 Review the MRP

Buyer QA or

FKR and QA/Inhouse will review the MRP in detail prior to the actual meeting to

identify all outstanding issues. The focus in the PPM will be to discuss all

outstanding issues that may impact bulk production quality.

1.

PO sheet & GSS/techpack

2.

Approved fabric swatch

3.

Approved trims cards

4.

Approved Pre-Production sample with comments

5.

Line review report

6.

Packing method

7.

Test report (fabric/yarn/leather

+ product)

8.

Discuss factory production plan

and capacity review and prepare the Weekly Production Status Chart

3.2 Inspection guideline for Full / Jump size Set

1. Study MRP file in detail and mark down any outstanding issues.

2. Study brand approved standard with approval comments.

3.

Check Full / Jump Size Set

sample styling against GSS and brand approved standard.

4. Check Full / Jump Size Set sample for the following:

4.1 Color tone

4.2 Hand feel

and washing effect, if GMT washing

4.3 Construction

(knit or woven,)

4.4 Fabric

weight / density / GMT weight for sweater

4.5 Review internal

fabric shrinkage test report vs. BV / ITS fabric test report

5. Measure all Full / Jump Size Set samples and complete measurement

sheet.

6. Check size grading, pattern and overall silhouette on each size

sample

6.1 Fabric shrinkage vs. pattern builds in shrinkage

% allowance

6.2 Seam allowance

6.3 Compare old pattern vs. corrected pattern per fit

comments

6.4 Pattern grading vs. size spec grading vs. full

size set sample measurement grading …

6.5 Pocket and button placement grading

6.6 Overall silhouette balance from

S->M->L->XL

7. Fit testing on dummy

7.1 Aesthetic

7.2 Balance

7.3 Movement on

armhole, chest, shoulder and all join seam strength by wear test.

8. Check cutting, sewing construction and workmanship.

8.1 Max no of

plies for fabric spreading

8.2 Max no of

ply and height for cutting

8.3 nap down or

up, cutting direction

8.4 Stitching

type and density

8.5 Seam

construction & allowance

8.6 Needle, gauge,

ball point or …

8.7 Collar /

cuff / pocket setting and placement

8.8 Specialized

machine, tucking,

8.9 Folder,

guides, attachment

9. Check Full / Jump Size Set sample trim quality, color matching and

label placement

9.1 Button-size,

lock stitching,

9.2 Zipper-length,

zipper head size / opening direction

9.3 Functional

check

9.4 Color

matching

9.5 Label placement

and sewing method.

9.6 Care

instruction vs. lab test report.

9.7 Interlining,

fusing temperature/pressure/speed test report…

10. Any special Embroidery \ Print quality and placement.

11. Check Full / Jump Size Set sample product safety and functional parts

11.1.

Alert vendor/factory Tech should make sure

pocket construction, small parts and functional parts meet Gap testing requirement from

sample development stage.

11.2.

Enhance vendor/factory field QA/DA double

check this part with in-house test report before PP meeting with GIS PQA if

needed.

11.3.

GIS PQA /DA double check pocket

construction and small parts during PP meeting before mass production.

11.4.

Encourage DA/GIS PQA to loop in PI/Testing

for consultation if they have questions and challenges regarding pocket construction

and small parts before PP meeting.

11.5. Min neck strength, pocket opening join seams and all weak points

11.6. Drawstrings

11.7. Small parts attachment

12. Study special GMT wash (Dry & Wet processing) effects and hand

feel

12.1 Washed

blanket with approved washing formula.

12.2 Hand

sanding, whiskers, tacking

12.3 Approved washed

shade band (light / med / dark)

12.4 Washed

standard

13. Study folding and packing method, plan for pre-pack check at pilot

stage

14. Review with production team on the key

product control points and inspection procedures

14.1 From left to right (Sleeve to sleeve)

14.2 From top to bottom (Collar to hem)

14.3 From outside to inside (stitching and seam

allowance inside…). For inside, from bottom, check up to the care label

position or 4” inches up. For top, open all buttons/ zippers to check inside. No

need to turn garment all inside out.

14.4 Key attachment inspections (Embroidery, print,

sequence, beads…etc) to ensure no sharp edges and un-attachment.

14.5 Study overall balance.

3.3 Bulk Fabric and Trims Quality

- Review factory’s internal fabric and trims inspection reports

1.1 Review shade

band and lots: side to side, side to center, and end to end.

1.2 Review shrinkage

report for fabric / trims (before and after washing, ironing)

1.3 Review internal interlining fusing report, if

applicable. (type, fusing temperature, pressing, speed)

1.4 Review functionality and visual consistence of

bulk trims.

3.4 Aesthetic and Construction Recommendations

The

Vendor/Factory will provide the following by Department and by Style:

1.

Identify where key production

control points will be inserted into the line

2.

Recommend the best solutions

for mass production

3.5 Post Meeting Documentation

The Vendor/Factory

will complete all post meeting documentation.

1.

Record all production control

points, quality control points and Time & Action (T&A) plan.

2.

Complete the Pre-Production meeting report.

3.

Distribute PP meeting report to

production teams and include a copy in the MRP for DA follow up

4.

Follow up Pilot Run/TOP sample submission.

4.1 Follow up items

1.

Factory production team

supervisors are accountable to ensure that all production control points in PP

meeting are implemented with the line workers before bulk production. The date of implementation is documented on

the PP meeting report.

2. QA buyer / Factory Key

Representative (FKR) and QA/Inhouse will follows-up T & A, all production control

and quality control points on site and verify the effectiveness.

3.

As needed, Buyer QA/ FKR and QA/Inhouse may

set up additional meetings with factory departments where there is more

production risk.

4.

FKR

and QA complete PP meeting report and include a copy in the MRP for future

production reference. Vendor/factory

will fax/email the completed PP meeting report to buyer pusat upon requested.

5.

Pre-production meeting report must

be available for all department supervisors and in-house QA for execution and

monitoring.

4.2 Successful Pre-Production Meeting

1.

Construction requirements and

aesthetic details are clearly conveyed to the Vendor/Factory

2.

All factory leaders are aligned

on the production approach

3.

All PP meeting report states

production control, quality control points and T & A are implemented

effectively.

4.

All potential construction

issues are discussed and factory recommends solutions prior to bulk production

or communicate with Buyer ManagerQA, PI, WP accordingly when needed.

I live in Madagascar ( East Africa),and life is worth living comfortably for me and my family now and really have never seen goodness shown to me this much in my life as I have been going through a problem as seriously as my son found a terrible accident last two weeks, and the doctors states that he needs to undergo a delicate surgery for him to be able to walk again and I could not pay the bills, then your surgery went to the bank to borrow and reject me saying that I have no credit card, from there i run to my father and he was not able to help, then when I was browsing through yahoo answers and i came across a loan lender Mr, Benjamin Breil Lee, offering loans at affordable interest rate I had no choice but to give it an attempt and surprisingly it was all like a dream, I got a loan of $ 110,000.00 to paid for my son surgery then get myself a comfortable business to help me going as well. I thank God today is good and you can walk and is working and the burden is longer so much on me more and we can feed well and my family is happy today and i said to myself that I will mourn aloud in the world of the wonders of God to me through this God fearing lender Mr Benjamin Breil Lee and I would advise anyone in genuine and serious need of loan to contact this God-fearing man on ...... 247officedept@gmail.com through .. and I want you all to pray for this man for me or Chat with him on whatsapp +1-989-394-3740 as well.

BalasHapusThank you